The project becomes a reality

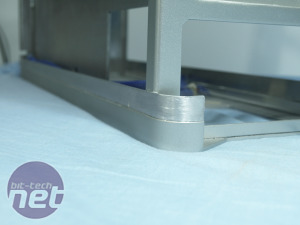

The very first stage was to make the basic frame of the case, which included the front,floor, back, and motherboard tray.Click to enlarge

Each section was cut using a jigsaw then filed down to the precise measurement I required, often accurate to half a mm or less. In order to stop the jigsaw dragging on the comparatively soft aluminium I stuck a piece of cardboard onto the bottom of the jigsaw which makes it glide with ease across the aluminium. Each section was then taped together to double check that all the dimensions were perfect.

Then once the panels had been given a brushed effect using Wet & Dry, all the panels were brazed together with a large propane torch and Durafix aluminium brazing rods to form a rigid frame. Once the frame had cooled down, epoxy resin was used to further secure each panel:

Click to enlarge

Some sections were then spray painted to hide all the joins between the different sections of aluminium:

Click to enlarge

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.